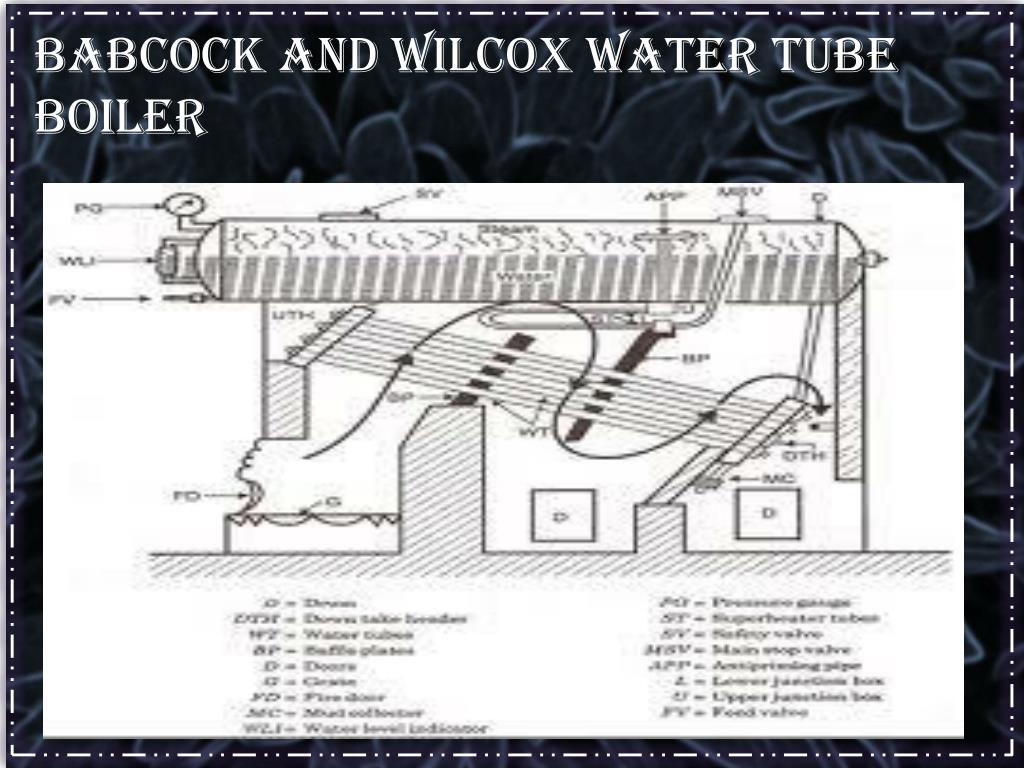

Parts of Babcock and Wilcox Boilerįollowing are the important parts of Babcock and Wilcox Boiler. The dampers are used to regulate the draught and are operated by a chain and a pulley. The firebricks baffle wall deflected the hot gases and help the hot gases to leave the chimney. Accordi chitarra.There is a slow-moving chain on which coal is fed from the hopper. Water level must be carefully watched during the operation of the Babcock and Wilcox boiler. In the case if feed water is not continuously supplied even for a short period of time, the boiler gets overheated.

That’s why water treatment is must before feeding into the boiler. In case of impure and sedimentary water, scale may deposit in the tubes and this leads to overheating and bursting of tubes.

It is the only boiler that is used to generate large quantity of heat in power stations.Replacement of defective tubes is easy.The high pressure steam so generated is used to produce electricity. The Babcock and Wilcox boiler are generally used to produce high pressure steam in power generation industries. The superheated steam from the steam stop valve is either collected in a steam drum or made to strike on the steam turbine for electricity generation.It increases the temperature of steam to desired level and transfers it to the steam stop valve. The superheater receives the water free steam from the anti-priming pipe.This anti-priming pipe filters the water content from the steam and allows only dry steam to enter into superheater. An anti-priming pipe is provided in the drum.The steam generated is moved upward and through up take header it gets collected at upper side in the boiler drum.

0 kommentar(er)

0 kommentar(er)